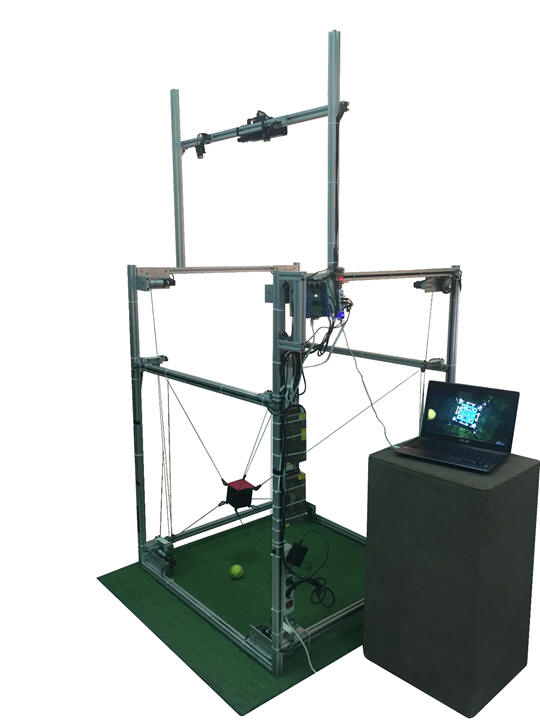

Design and Manufacturing of an 8 DOF Cable Robot (RoboCab)

The RoboCab is a cable-dirven redundant parallel robot with six degrees of freedom and two degrees of redundancy. The Moving Platform (MP) is an aluminium cubic with an inertial measurement unit mounted on to measure the resultant rotation. Output rotation data is driven into an onboard processor where attitude and heading reference system and Madgwick algorithm are implemented. The processed data on the board is wirelessly transferred to the PC using bluetooth connection module. The camera vision of the robot gives the position information and is composed of two Microsoft LifeCam Cinema webcams mounted on the top sides of the robot. Load cells also perform cable force feedback to ensure positive tension in cables.