Design and Manufacturing of an Industrial Automated Casting Machine

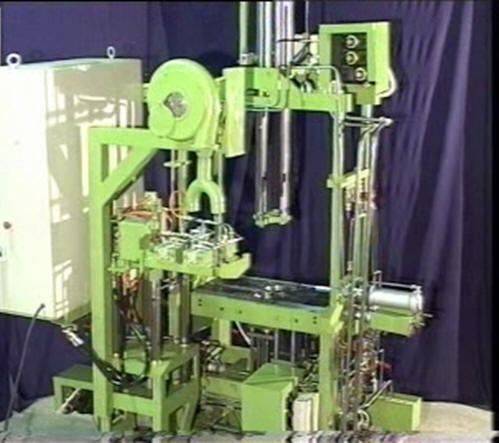

Increasing demands for high quality products, has motivated investigation of exploiting robotic production cells. Various ARAS projects were defined in late 1990's, to establish a casting robotic cell. One of the main elements for such a cell is an Industrial Automated Welding Machine. This was thoroughly designed with the specifications described in the following, and manufactured as shown below. The machine performs a gravity casting process in permanent water-cooled moulds. Mould parts and cores are automatically separated from the product after solidification. A robot manipulator transfers product to a cooling station where it is cooled by virtue of air and/or water currents. The casting machine is suitable for casting double Aluminum pistons of φ65 mm ~ φ92 mm with a core distance of 150 mm. Six machines were manufactured in early 2000's which are still used.

.