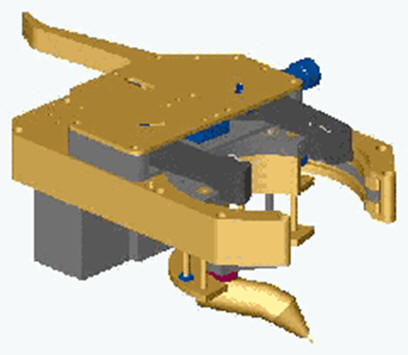

Design and Manufacturing of an Industrial Welding Robot

Automatic Pipe Welding Robot was designed for automated welding of nozzles to headers used in power plant boilers. The radial welding of these pipes with different radii necessitates saddle curves tracking with adjustable dimensions. The mechanical subsystems controlled by individual micro-controllers being supervised by a central controller, provide a fully automated solution to this application, despite the geometrical limitations. A saddle curve is formed at the intersection of nozzle to the header. The welding torch needs three degrees of freedom to go through this curve:

• A revolute motion around the nozzle;

• A prismatic movement along the nozzle axis;

• A third degree of freedom is used to move the torch along the nozzle radius.

These three motions are supported by 3 gear groups. A general view of this mechanism is shown in the figure.