Flexible Electronics

Stretchable electronics

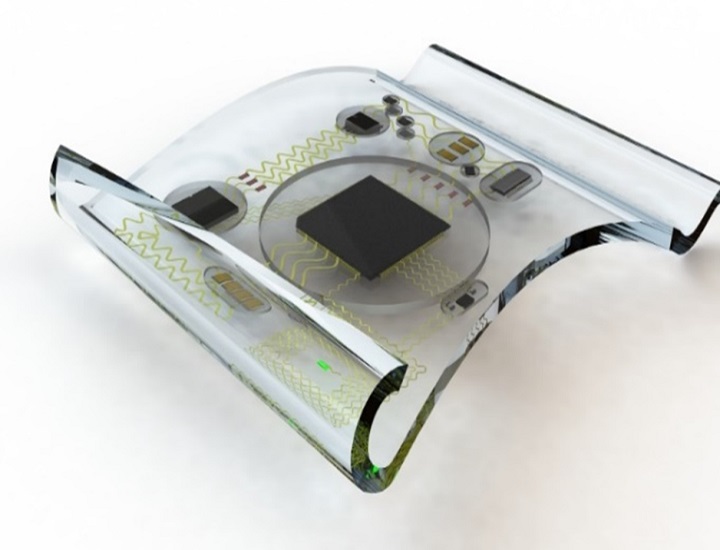

represent a transformative field that merges the high

performance of traditional rigid electronics with the

flexibility and conformability of soft materials. This

technology enables devices to bend, stretch, and twist

without losing functionality, making it ideal for

applications in biomedicine, wearable health monitors,

and flexible sensors. A key challenge lies in

integrating rigid components, such as silicon-based

complementary metal-oxide-semiconductor (CMOS) chips,

into soft, stretchable substrates. Silicon, with a Young

s modulus of approximately 170 GPa, is far stiffer than

soft materials mimicking human tissue (Young s modulus

~100 kPa), leading to delamination and failure under

strain.

To address this,

researchers have developed innovative strategies, such

as embedding "thick" silicon chips (>10 μm) into

stretchable systems using material gradients. These

gradients gradually transition stiffness between rigid

and soft materials, minimizing stress concentrations at

interfaces. For instance, polydimethylsiloxane (PDMS)

with varying base-to-curing agent ratios has been used

to create intermediate layers that significantly enhance

strain tolerance, achieving up to 140% strain before

failure compared to ~20% for conventional designs.

Finite element analysis and

experimental studies have demonstrated that these

material gradients reduce energy release rates, delaying

crack propagation and delamination. Applications range

from wearable electronics that conform to skin to

advanced biomaterials and flexible actuators. Despite

significant progress, challenges remain in achieving

higher transistor densities and improving organic

semiconductor reliability. Future innovations may

include continuous stiffness gradients or additional

material layers to further refine performance.

This field holds immense

potential for revolutionizing how electronics interact

with the human body and the environment, paving the way

for next-generation technologies in healthcare,

robotics, and beyond.

.

Description

This study

addresses the challenge of integrating

rigid silicon-based electronics into

stretchable substrates, a key hurdle in

flexible electronics. By embedding

"thick" silicon chips (>10 μm) and using

material gradients, the authors achieve

enhanced flexibility and durability.

Polydimethylsiloxane (PDMS) with varying

stiffness ratios creates intermediate

layers, reducing delamination risks.

Structures with these gradients

withstand up to 140% strain, compared to

20% for conventional designs. Finite

element analysis and experiments confirm

reduced energy release rates at

interfaces, preventing crack

propagation. This innovation enables

stretchable systems to embed standard

CMOS electronics, paving the way for

advanced wearable health monitors and

biomedical devices.

1.

References

- Ref 1

- Ref 2

- Ref 3